AI-Driven PCBA Manufacturing Platform

From real production lines to global delivery — LinkPCBA connects precision manufacturing with verified engineering.

Watch how our intelligent MES and SMT systems integrate every step — from circuit boards to final assemblies.

From Circuit Boards to Finished Products — Complete OEM & ODM Manufacturing

PCB Manufacturing

High-quality PCB fabrication for single-layer, multilayer, HDI, and aluminum boards. We ensure ±0.075 mm precision, controlled impedance (±5 %), and strict Class 3 compliance across all fabrication stages.

PCB Assembly

Advanced SMT and through-hole assembly with AOI, X-Ray, and ICT testing. Our 10 Yamaha SMT lines and 4 DIP lines ensure both speed and reliability for prototypes and mass production.

OEM & ODM Integration

From design optimization to box-build assembly, we provide flexible OEM and ODM solutions. Every project is verified by the LinkPCBA Engineering Department and traceable through MES for transparency and consistency.

Comprehensive PCBA Manufacturing and Development Services

From early-stage design to box-build integration, LinkPCBA provides end-to-end electronics manufacturing solutions for global OEM & ODM clients. Each step follows ISO9001 and IPC Class 3 standards, ensuring precision, traceability, and proven reliability.

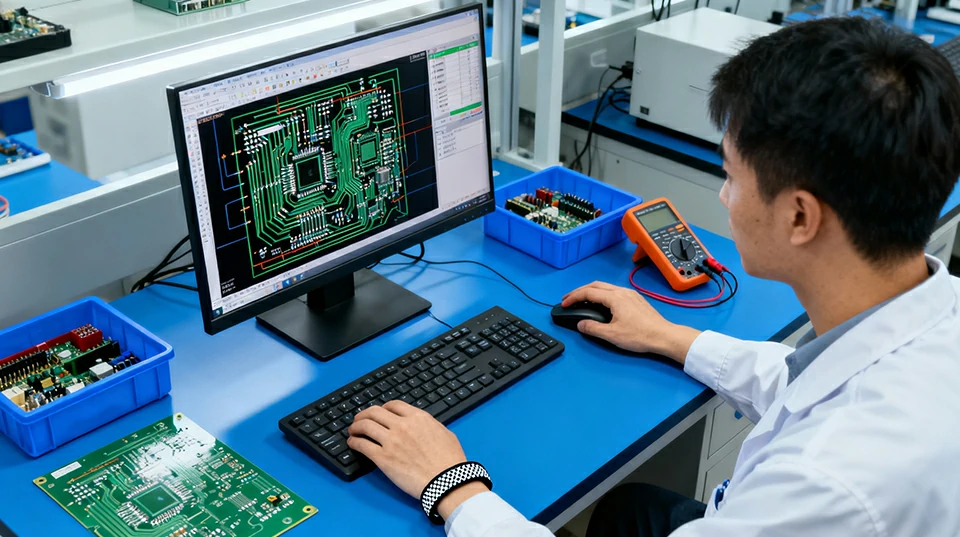

Design & R&D — From Concept to Manufacturable Engineering

- Professional R&D team for schematic design, PCB layout, and firmware development.

- AI-driven DFM analysis minimizes design errors and improves production yield.

- 17+ years of cross-industry experience in automotive, IoT, and medical fields.

- Design verification under IPC and electrical performance standards.

- Accelerated prototyping cycles for faster time-to-market.

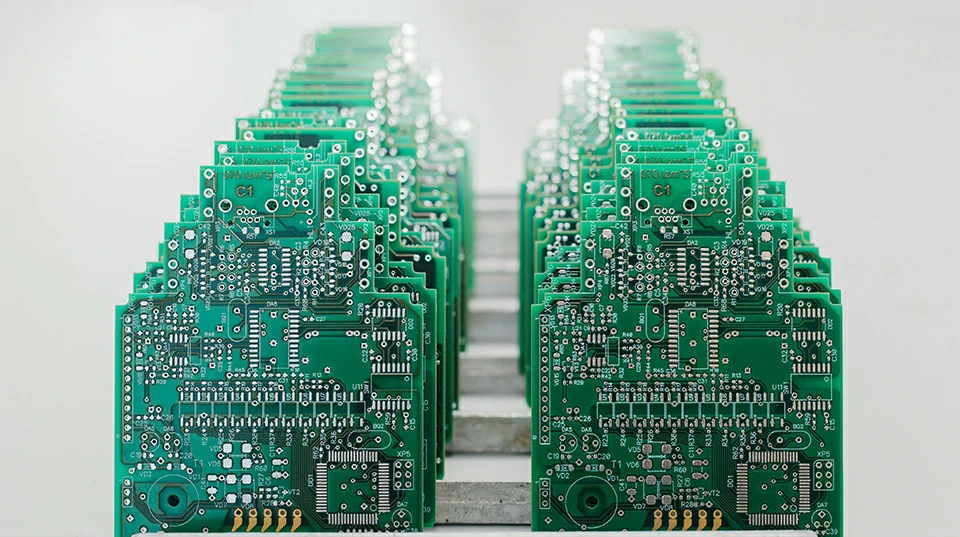

PCB Manufacturing — Precision Boards for Every Application

- Advanced multilayer, HDI, and high-frequency PCB fabrication.

- ±0.075 mm dimensional tolerance with impedance control ±5 %.

- Materials include FR-4, Rogers, and Aluminum core for thermal management.

- IPC-6012 Class 3 certified processes for critical reliability.

- AOI, micro-sectioning, and impedance verification for quality assurance.

PCB Assembly — High-Speed SMT & Reliable THT Integration

- 10 Yamaha YSM SMT lines + 4 DIP lines for flexible capacity.

- Component range from 0201 to BGA 0.25 mm pitch.

- Nitrogen reflow ensures void-free solder joints and thermal balance.

- AOI, X-Ray, and ICT testing provide 100 % inspection coverage.

- Capable of both prototype and high-volume production with equal quality.

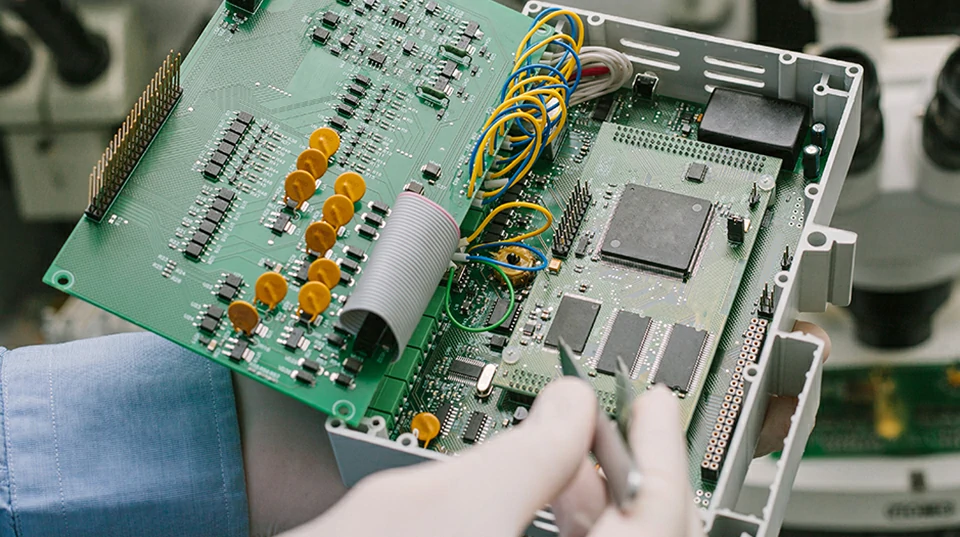

Box-Build Assembly — Complete Product Integration & Functional Testing

- ESD-protected assembly area for safe product integration.

- Enclosure installation, cable harnessing, and connector assembly.

- Firmware burning, labeling, and configuration verification.

- Functional testing and 48-hour burn-in validation before shipment.

- ISO9001-certified process for consistent end-product quality.

Box-Build Assembly

Complete product integration from PCBA to final assembly. Our ESD-safe production lines handle enclosure installation, cable harnessing, and firmware programming, ensuring every product passes functional and burn-in testing before shipment.

Why Choose Link PCBA

What Makes Link PCBA Stand Out in PCBA Manufacturing

One-on-one engineering support providing fast technical response, real-time feedback, and seamless project communication from prototype to mass production.

Three advanced manufacturing centers in Shenzhen specializing in PCB fabrication, SMT assembly, and final box-build integration, supported by MES traceability and digital quality control.

Complete one-stop PCBA and EMS solutions — covering PCB production, SMT, DIP, testing, and finished product assembly — ensuring precision and efficiency at every stage.

Free DFM, Gerber, and BOM review with expert optimization advice to improve manufacturability, reduce cost, and enhance long-term product reliability.

Certified quality management system compliant with ISO9001, IATF16949, ISO13485, RoHS, REACH, and IPC-A-610 Class 3 standards, ensuring consistent quality across all projects.

Strong EMS capability serving global clients in automotive, medical, IoT, communication, and security electronics industries, backed by verified process validation and on-time delivery.

What Makes LinkPCBA Different

Our advantages are built on proven engineering systems, digital transparency, and real manufacturing capability. Each principle ensures long-term success and measurable quality for our partners.

Smart Manufacturing Integration

By combining AI-based DFM, MES traceability, and ERP data synchronization, LinkPCBA achieves complete digital control from quotation to shipment. Every project is monitored for precision, cost, and process stability.

Precision & Reliability at Every Step

Our production integrates Yamaha SMT placement (±0.03 mm), nitrogen reflow soldering, and automated AOI/X-Ray inspection, ensuring unmatched consistency and solder joint reliability for all assemblies.

Verified Quality & Transparent Data

All test results and production metrics are validated under IPC-TM-650 and ISO9001 protocols. Customers receive traceable documentation and process reports for each lot, enhancing trust and accountability.

Global Engineering Collaboration

Engineering teams across Shenzhen, Vietnam, and the U.S. collaborate seamlessly, providing localized support, fast feedback, and real-time technical communication for international clients.

Sustainable & Future-Ready Manufacturing

We operate under RoHS/REACH compliance and energy-efficient standards, continuously innovating with AI optimization to reduce material waste and support environmentally responsible manufacturing.

Manufacturing Scale and Global Presence

As an established PCBA manufacturer, LinkPCBA combines engineering expertise, advanced facilities, and intelligent production systems to deliver precision manufacturing on a global scale. This foundation ensures consistent quality, rapid response, and reliable supply for every client project.

Headquartered in Shenzhen, LinkPCBA operates as a full-service PCBA manufacturer integrating PCB fabrication, SMT assembly, testing, and final box-build under one digital system. Three advanced manufacturing centers across Shenzhen specialize in different production stages — from multilayer PCB manufacturing to precision SMT and complete product integration. Through an MES-driven platform, every process remains traceable, data-based, and quality verified, ensuring reliable output for both OEM and ODM clients.

A team of over 300 engineers and skilled technicians supports 10 SMT lines, 4 DIP lines, and dedicated testing facilities, enabling both rapid prototyping and stable mass production. With seventeen years of experience and certifications including ISO9001, IATF16949, ISO13485, RoHS, REACH, and IPC-A-610 Class 3, LinkPCBA delivers verified quality and sustainable manufacturing for global customers in automotive, medical, IoT, industrial, and communication sectors across 200+ countries.

Industries We Serve

LinkPCBA delivers high-reliability PCBA solutions for emerging and established markets. Our manufacturing expertise supports innovation across multiple sectors, ensuring each application meets strict quality, safety, and performance standards.

Security & Communication Systems

Stable and interference-resistant PCBA for surveillance, access control, and communication infrastructure. Designed for 24/7 operation with EMC protection, shielding, and long-term component reliability.

Automotive Electronics

Precision PCBA manufacturing for automotive control units, ADAS systems, and EV battery management. All assemblies meet IPC Class 3 and IATF16949 standards for vibration resistance and long-term reliability.

Industrial Control Systems

Durable PCBA solutions for automation, robotics, and power management. High-temperature and high-current designs are validated through AOI, X-Ray, and functional testing to guarantee stability in demanding environments.

Medical Devices

Certified ISO13485 manufacturing for diagnostic, monitoring, and portable medical electronics. Every production stage follows traceable quality control to ensure safety, accuracy, and compliance with global medical regulations.

IoT & Smart Devices

Compact, energy-efficient assemblies for IoT modules, wearables, and smart-home systems. RF optimization and multi-protocol compatibility (Wi-Fi, BLE, LoRa) deliver reliable connectivity in small-form designs.

New Energy Systems

Reliable PCBA manufacturing for renewable energy applications, including solar inverters, energy storage systems, and EV charging infrastructure. Boards are designed for high current, heat resistance, and long operational lifespan under continuous load.

Trusted by Global Electronics Clients

Hear from our partners about quality, reliability, and service excellence

We’ve been working with LingkPCBA for over a year now, and their technical team has been incredible. They handled our prototype changes quickly, and the communication was always clear. What impressed me most was their ability to balance cost and quality — something rare in offshore PCBA manufacturing.

German clients value precision and traceability — and LingkPCBA delivered both. Their production traceability system, inspection reports, and material transparency met our internal audit standards. The cooperation feels smooth and reliable, with strong communication and consistency in every batch.

We worked with LingkPCBA on a complex OEM project.

Their team understood our requirements and delivered

high-quality PCBA on time. Communication was clear,

costs were well-managed, and they supported us

through every step of prototyping and production.

We are very satisfied and would work with them again.

We chose LingkPCBA because of their fast response and willingness to customize. For our industrial controllers, we needed DIP + SMT mixed assembly with strict testing. They handled it perfectly. The packaging, labeling, and documents were all done to EU standards — a truly professional service.

The responsiveness and efficiency of LingkPCBA’s team are top-notch. Even with small batch orders, they treat us seriously and provide detailed progress updates. The pricing is competitive, and their turnaround speed helps us meet tight project schedules. Definitely a trustworthy long-term partner.

PCBA Insights & News

Latest company updates, industry trends, and tech tips.

Industry News/Enterprise Dynamics

Exciting Preview: Exclusive Highlights at the 2024 Munichshanghai Electronics sh

Exciting Preview: Exclusive Highlights at the 2024 Munichshanghai Electronics show

Exciting Preview: Exclusive Highlights at the 2024 Munichshanghai Electronics show

technical discussion

Service You Can Trust

Professional support at every step.

Quality Builds Trust

Reliable products, consistent performance.

Value You Deserve

Competitive pricing without compromise.

On-Time Always

On-time, every time, no excuses.

Data Protected

Your information is fully protected.