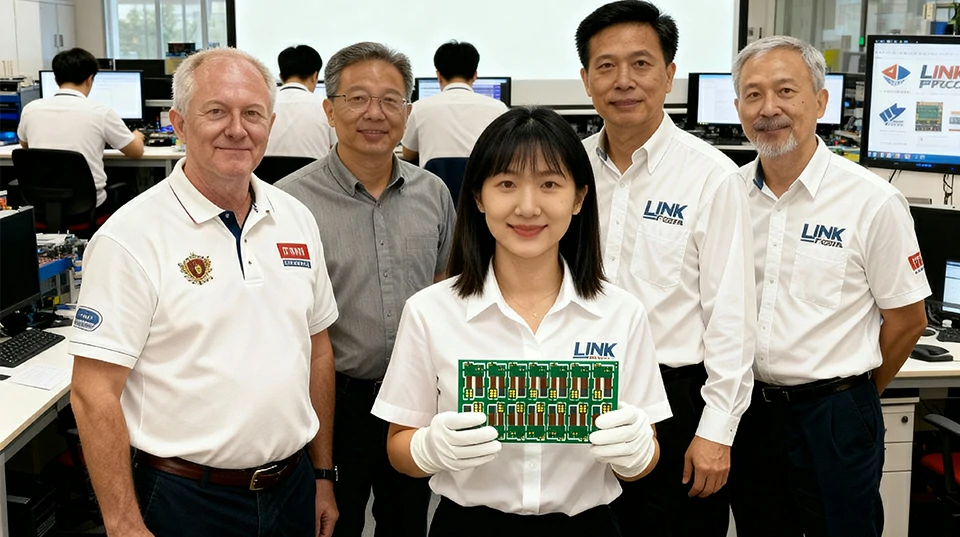

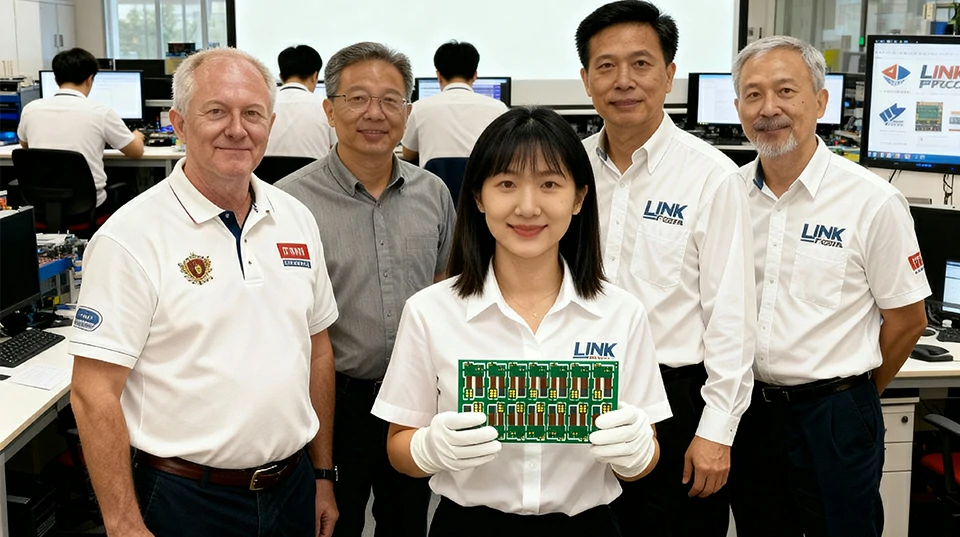

Through-Hole / THT Assembly Services — Wave Soldering & High-Reliability Manual Soldering

LinkPCBA provides high-reliability Through-Hole (THT) Assembly Services including wave soldering, selective soldering, and IPC-certified manual soldering.

Our Shenzhen-based production lines support power electronics, industrial control, automotive modules, and mixed-technology PCBAs, ensuring stable mechanical strength, high current capability, and long-term durability for demanding applications.

Why OEM & ODM Clients Choose LinkPCBA for THT Assembly

High-Reliability Wave & Selective Soldering

- Consistent solder quality for high-current and high-thermal-mass components.

IPC-Certified Manual Soldering

- Certified technicians handle connectors, transformers, relays, terminals, and other special parts.

Suitable for Power & Automotive Applications

- Strong mechanical strength, vibration resistance, and long-term reliability.

Complete Process Control

- Pre-bake, flux control, solder pot maintenance, solder dross removal, and thermal profiling.

Mixed Assembly Support(SMT + THT)

- Integrated workflow with SMT reflow + THT wave soldering in one production system.

SMT Assembly Capabilities

Component Capability

- Pin headers & connectors

- Transformers & inductors

- Relays, fuses, large capacitors

- High-current terminals

- Screw terminals

- Mechanical components

Process Capability

- Wave soldering

- Selective soldering

- Manual soldering

- DIP insertion (auto / semi-auto)

- High-current joint reinforcement

- Thermal mass management

- Lead-free soldering

Board Type Support

- Power electronics

- Industrial control boards

- Automotive modules

- LED drivers

- Charging modules

- Mixed signal boards

Engineering Support for THT

Our engineering team ensures repeatable solder quality even for complex assemblies.

- Component lead forming & trimming

- Thermal profiling for wave soldering

- Solder joint optimization

- Flux selection & control

- Avoiding shadowing, bridging, and icicles

- Fixture design & wave pallets

- Heavy component reinforcement

This engineering involvement significantly reduces defects and improves reliability.

Quality System & THT Process Control

Comprehensive QC Workflow

IQC → Pre-process check → Wave solder setup → IPQC → AOI (if applicable) → Visual inspection → FQC → OQC

THT Quality Controls

- Flux concentration & uniformity testing

- Solder pot maintenance & temperature stability

- Dwell time control

- Wetting balance measurement

- Proper lead trimming & hole solder fill verification

Inspection Capabilities

- Visual inspection

- Solder joint analysis

- Hole-fill percentage checking

- Pull strength test

- Burn-in & aging test (optional)

Standards

- IPC-A-610 Class 2 / Class 3

- RoHS / REACH compliance

- Full batch traceability

Applications

THT assemblies delivered by LinkPCBA are widely used in:

Industrial automation equipment

Power supply & power electronics

Automotive electronics

New energy systems

Medical & testing devices

Consumer electronics with mixed technology

Security & Communication Systems

Stable and interference-resistant PCBA for surveillance, access control, and communication infrastructure. Designed for 24/7 operation with EMC protection, shielding, and long-term component reliability.

Automotive Electronics

Precision PCBA manufacturing for automotive control units, ADAS systems, and EV battery management. All assemblies meet IPC Class 3 and IATF16949 standards for vibration resistance and long-term reliability.

Industrial Control Systems

Durable PCBA solutions for automation, robotics, and power management. High-temperature and high-current designs are validated through AOI, X-Ray, and functional testing to guarantee stability in demanding environments.

Medical Devices

Certified ISO13485 manufacturing for diagnostic, monitoring, and portable medical electronics. Every production stage follows traceable quality control to ensure safety, accuracy, and compliance with global medical regulations.

IoT & Smart Devices

Compact, energy-efficient assemblies for IoT modules, wearables, and smart-home systems. RF optimization and multi-protocol compatibility (Wi-Fi, BLE, LoRa) deliver reliable connectivity in small-form designs.

New Energy Systems

Reliable PCBA manufacturing for renewable energy applications, including solar inverters, energy storage systems, and EV charging infrastructure. Boards are designed for high current, heat resistance, and long operational lifespan under continuous load.

Case Studies

Case 1 — High-Current Industrial Power Module

- Selective soldering for large copper areas

- Achieved 100% solder hole fill

- Reinforced terminals for vibration resistance

- Stable delivery over 24+ months

Case 2 — Automotive Sensor Interface Board

- Mixed SMT + THT process

- Zero bridging rate across 6 pilot batches

- Passed vibration & thermal cycling tests

FAQ — Through-Hole / THT Assembly

Connectors, transformers, relays, terminals, fuses, large capacitors, etc.

Yes, both.

Yes, it is our standard process.

IPC-A-610 Class 2 / 3.

Yes, including hole-fill checking and mechanical strength evaluation.

Start Your THT Assembly Project Today

Reliable Soldering • Power & Automotive Grade • Full Process Control

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team