AI Computing & Edge AI PCB / PCBA Manufacturing

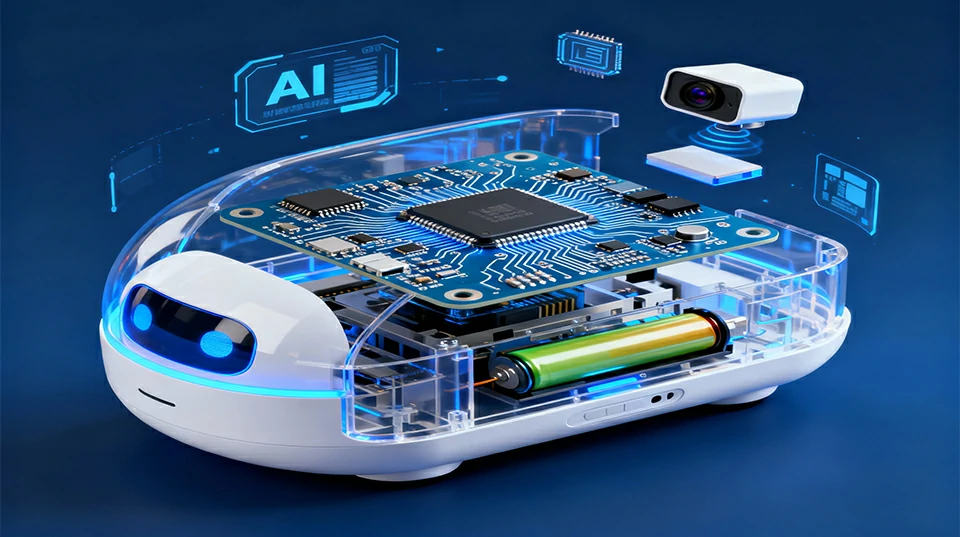

AI computing and edge AI devices require high processing capability, stable signal integrity, optimized thermal performance, and reliable high-density PCB manufacturing. LinkPCBA provides complete PCB and PCBA manufacturing solutions for AI accelerator modules, edge inference devices, smart cameras, AI sensors, embedded AI processors, and industrial edge computing systems.

With three Shenzhen manufacturing centers and a full one-stop workflow—from PCB fabrication to SMT, DIP, testing, and box-build—we support global AI hardware OEM & ODM projects with strong engineering support, stable quality, and fast mass-production capability.

Customer Project Scenario — High-Density AI Hardware

A technology company partnered with LinkPCBA to produce an edge AI inference module for smart city and industrial automation applications.

The project required:

- High-speed signal integrity for AI processors and memory

- Stable power delivery for high-computation loads

- High-density multi-layer HDI PCB for compact edge devices

- Advanced thermal management for continuous operation

- Fast prototyping + rapid iteration cycle

- Smooth volume ramp-up for global deployment

LinkPCBA provided a validated PCB & PCBA manufacturing solution enabling fast R&D cycles and reliable mass production.

Technical Challenges in AI & Edge Computing Hardware

AI computing boards involve complex high-speed and high-density engineering challenges:

- High-speed interfaces (PCIe, MIPI, LPDDR, USB 3.x)

Signal routing must ensure impedance accuracy and low noise. - High-power and high-current operation

AI accelerators require stable power delivery and thermal dissipation. - Dense PCB architecture

Compact AI devices require HDI, blind/buried vias, microvias, and precise stack-up. - Thermal management

AI processors generate significant heat during inference and continuous operation. - Mixed-signal complexity

RF modules, sensors, digital blocks, and high-speed cores often coexist.

LinkPCBA Manufacturing Solution for AI Computing & Edge AI

Engineering Support

DFM & DFA for high-speed AI circuits

Impedance-controlled routing for PCIe, DDR, USB, MIPI

Power delivery network (PDN) optimization

Thermal optimization: copper pours, thermal vias, heat spreading

Stack-up design for HDI and high-speed routing

PCB Manufacturing

6–20 layer HDI PCBs for AI hardware

Microvia, blind/buried via stack-ups

Controlled impedance for high-speed signals

High-Tg laminates for thermal stability

ENIG / ENEPIG for processor & BGA interfaces

LDI imaging for fine-line and high-density routing

PCBA Assembly

BGA, LGA, QFN, PoP component assembly

High-precision SMT for fine-pitch AI processors

X-ray inspection for dense packages and hidden joints

DIP / selective solder for connectors and power modules

Conformal coating optional for industrial edge devices

Full traceability for AI product lifecycle management

Functional & Performance Testing

High-speed interface testing

Power cycling and consumption verification

Functional AI module testing

Thermal stability & heat dissipation validation

Environmental reliability testing

AI Production Capability

With three Shenzhen production centers, LinkPCBA offers:

- Rapid prototyping → NPI → Mass production

- Fast 24-hour prototype build

- Stable sourcing for MCUs, NPUs, AI processors, memory

- Quick ECN support

- Dedicated engineering teams for AI hardware

We support complex AI boards from early R&D through mass deployment.

Quality Assurance & Thermal Reliability

AI hardware requires high-speed and high-density QA processes:

- 100% AOI & SPI

- X-ray for BGA, micro-BGA, PoP

- High-speed interface testing

- Thermal cycling & load testing

- Burn-in testing for long-term reliability

- Full documentation and batch traceability

We ensure stable performance for AI-driven applications.

AI & Edge Computing Application Segments We Support

Edge AI Inference Devices

Compact AI processing modules for real-time applications

AI Cameras & Vision Systems

Smart cameras, intelligent surveillance, image processing units

AI Accelerator Modules

NPU boards, micro AI accelerators, embedded AI processors

Smart Sensors & Industrial AI Nodes

Sensor fusion units, intelligent monitoring sensors

Embedded AI Gateways

Industrial IoT + AI edge computing platforms

Robotics & Automation AI Boards

Motion control + AI perception hardware

Why OEM & ODM Clients Choose LinkPCBA for AI & Edge Computing Manufacturing

- High-speed, high-density PCB expertise

HDI, microvias, controlled impedance, and high-speed routing. - Advanced SMT capability for AI processors

BGA, LGA, PoP, QFN assembly with X-ray quality control. - Strong engineering support

PDN, thermal, and high-speed optimization. - One-stop PCB & PCBA manufacturing

PCB + SMT + DIP + testing + box-build. - Fast prototyping & iteration speed

Critical for fast-evolving AI hardware development cycles.

Case Study — Edge AI Processing Module

LinkPCBA delivered:

- 10-layer HDI PCB

- Controlled impedance for high-speed buses

- BGA + PoP mixed assembly

- Thermal optimization with copper pours and thermal vias

- Full functional and thermal testing

The module met performance targets and successfully entered mass deployment.

FAQ — AI Computing / Edge AI PCB / PCBA

Yes. We support controlled impedance and high-speed routing.

Yes. We provide HDI stack-ups for compact AI devices.

Yes. We offer advanced SMT with X-ray validation.

Through thermal vias, copper pours, heat spreading, and reliability testing.

Yes. We offer fast 24-hour prototypes and quick ECN updates.

Start Your AI Hardware Project

LinkPCBA provides reliable PCB & PCBA manufacturing for AI computing and edge AI devices, supporting fast development cycles and scalable production.

Our engineering team responds within 24 hours.

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team