Automotive Electronics PCB / PCBA Manufacturing

Automotive electronics demand unmatched reliability, long-term performance stability, and zero-defect mass-production capability. LinkPCBA provides engineering-driven PCB and PCBA manufacturing solutions that fully comply with automotive-grade requirements, covering powertrain systems, ADAS modules, infotainment, safety electronics, EV battery management, and high-power control units.

With three Shenzhen manufacturing centers and a complete one-stop service chain—from PCB fabrication to SMT, DIP, testing, and final assembly—we support global OEM & ODM automotive programs with fast response, stable quality, and scalable production capacity.

Customer Project Scenario — High-Reliability Automotive Electronics

A global Tier-1 automotive electronics supplier partnered with LinkPCBA to produce a control board used in a fuel-injection ECU subsystem.

The project required:

- Stable performance under wide temperature ranges (-40°C to 125°C)

- Consistent impedance and multilayer reliability during high-current operation

- Automotive-grade solder joint durability and vibration resistance

- End-to-end traceability across all PCB and PCBA processes

- Small-batch verification followed by rapid volume ramp-up

LinkPCBA provided a fully validated PCB + PCBA manufacturing solution enabling early engineering verification and fast transition to mass production.

Technical Challenges Faced in Automotive Electronics

Automotive electronics operate in harsh and safety-critical environments. Common engineering challenges include:

- High-temperature and high-humidity endurance

Continuous operation in extreme conditions requires stable materials, precise lamination quality, and long-term dielectric reliability. - Vibration, shock, and fatigue resistance

Automotive modules must maintain solder joint strength and structural integrity over years of vibration cycles. - High-current and heat-management requirements

Power control units, BMS boards, and motors require thick-copper, low-loss structures, or thermal-enhanced PCB designs. - Zero-defect SMT and process repeatability

Automotive projects demand strict process control, detailed traceability, and batch-to-batch consistency. - Safety & functional reliability

From ADAS to braking systems, reliability and failure-proof performance are essential.

LinkPCBA Manufacturing Solution for Automotive Applications

Engineering Support

- DFM & DFA for automotive PCB stack-up, copper balancing, via design, and power routing

- Material guidance for FR-4 high-Tg, high-temperature substrates, heavy copper, and hybrid constructions

- Review for thermal paths, creepage distance, EMI/EMC mitigation, and high-current zones

PCB Manufacturing

- 2–20 layers automotive PCB with high-Tg laminates

- LDI fine-line imaging for tight trace/space control

- Heavy-copper (up to 6 oz) for power control units

- High-temperature solder mask and anti-oxidation surface finishes

- Controlled impedance for CAN, FlexRay, and Ethernet automotive networks

PCBA Assembly

- High-precision SMT lines with AOI, SPI, and auto-loading

- IPC Class 2 / Class 3 solder quality

- DIP wave soldering or selective solder for connectors and power modules

- Conformal coating, potting, and silicone application for harsh environments

- Full traceability: barcode labeling, lot tracking, and MES data logging

Functional Tests & Reliability Validation

- ICT, FCT, X-ray inspection

- Thermal aging, vibration tests, and load-current validation

- Burn-in verification for long-term reliability

Automotive-Grade Production Capability

With three Shenzhen production centers for PCB fabrication, SMT assembly, and box-build integration, LinkPCBA supports:

- Prototype + NPI + mass production

- 24-hour fast-turn samples

- Stable supply chain with automotive-grade components

- Engineering change response within hours

- Flexible production for small-batch EV/ADAS modules and high-volume consumer automotive electronics

We deliver consistent quality across all stages—from PCB blank fabrication to complete PCBA shipment.

Quality Assurance & Validation System

Automotive projects require long-term reliability, and our QA system ensures traceability and batch consistency:

- 100% AOI & SPI inspection

- Multiple X-ray checkpoints for BGA, QFN, and thermal pad components

- High-temperature reliability validation (Tg / thermal cycles)

- Conformal coating and insulation strength verification

- Complete documentation package for OEM & ODM automotive clients

Quality data is recorded and traceable for every lot.

Automotive Application Segments We Support

Powertrain & Engine Control

ECU, ignition control, fuel injection, and thermal management modules

ADAS & Vehicle Safety Systems

Radar modules, camera systems, LiDAR control boards, braking electronics

EV / Hybrid Systems

BMS boards, power inverter PCBs, on-board chargers, DC-DC converters

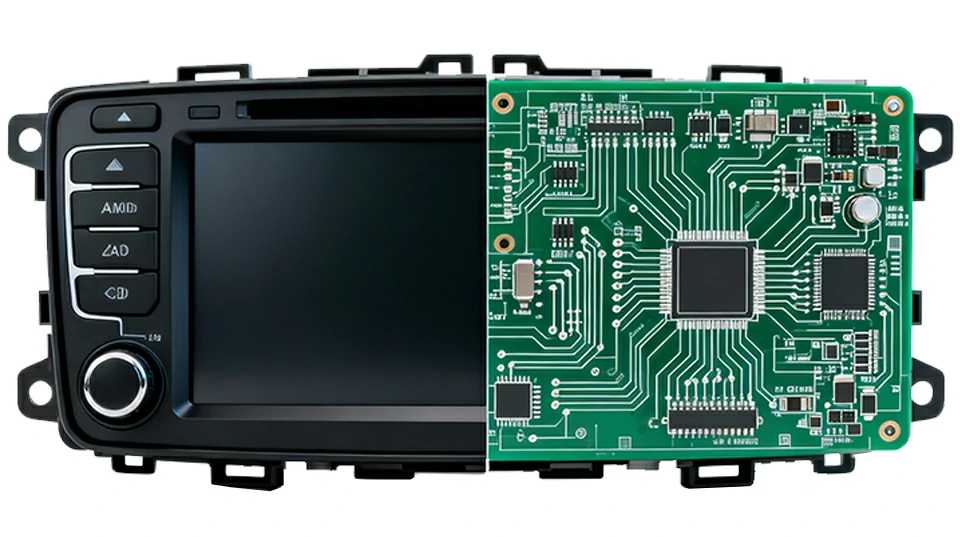

Infotainment & Connectivity

Car multimedia systems, displays, navigation units, connectivity modules

Body Electronics

Lighting systems, door controls, wiper modules, HVAC control units

Sensors & Actuators

Pressure sensors, speed sensors, position measurement and monitoring units

Why OEM & ODM Clients Choose LinkPCBA for Automotive Electronics

Automotive-grade reliability

- Stable materials, tight process control, strict SMT inspection, and long-term performance validation.

Full manufacturing chain under one system

- PCB fabrication + SMT + DIP + testing + coating + box-build = one accountable partner.

Fast engineering response

- 24-hour DFM, quick prototyping, and rapid ECN handling for evolving automotive designs.

Real production capability

- High-precision SMT lines, advanced PCB equipment, and stable sources for automotive components.

Professional communication & global delivery

- International sales & engineering team providing end-to-end support from quotation to shipment.

Case Study — Automotive ECU Control Board

LinkPCBA delivered:

- 8-layer high-Tg PCB

- Heavy-copper power layers + controlled impedance signal layers

- 0201 + high-current components mixed assembly

- Conformal coating + vibration resistance soldering

- Full functional testing and batch traceability

The project successfully transitioned from prototype to mass production with consistent quality and accelerated customer time-to-market.

FAQ — Automotive Electronics PCBA

Yes. We follow IPC Class 2 / Class 3 standards and provide full reliability validation, traceability, and stable mass-production capability.

We specialize in prototypes, NPI, and mass-production scaling for automotive clients.

Yes. We offer silicone, acrylic coating, and full protective processes.

Through heavy-copper PCB fabrication, optimized thermal design, and strict solder joint inspection.

Yes. We work with verified suppliers to provide stable sourcing and full material traceability.

Ready to Start Your Automotive Electronics Project?

LinkPCBA provides fast response, engineering-driven support, and reliable PCB/PCBA manufacturing for global automotive OEM & ODM programs.

Our team is ready to review your Gerber, BOM, and requirements within 24 hours.

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team