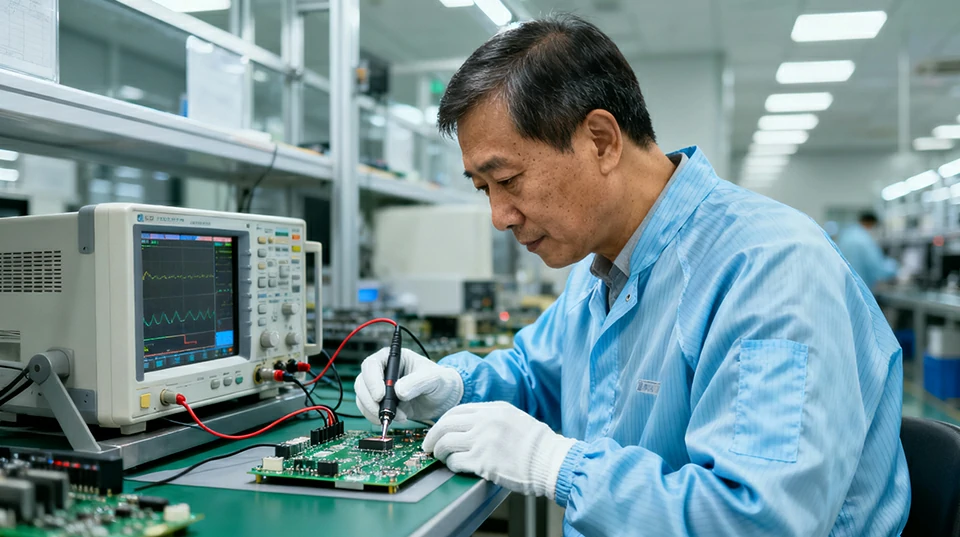

Box Build Assembly — Complete Product Integration & Final Assembly

LinkPCBA provides end-to-end Box Build Assembly services, delivering finished products that integrate PCBA, wiring, enclosures, mechanical components and full functional testing.

From engineering evaluation to final packaging, we support OEM & ODM customers to achieve reliable, scalable and production-ready finished products.

What Is Box Build Assembly

Box build assembly refers to the final integration stage of a complete product, including:

- PCBA installation

- Cable & harness assembly

- Mechanical and structural assembly

- Display, sensor and module integration

- Firmware loading & configuration

- Functional testing and final inspection

- Packaging, labeling and shipping preparation

It is the process of turning assembled PCBAs into finished, ready-to-ship devices.

Why Choose LinkPCBA for Box Build Assembly

Full OEM & ODM Integration

From PCB → PCBA → wiring → enclosure → final product, all steps executed under unified engineering control.

Engineering-Driven Assembly Process

Mechanical build instructions, cable routing plans, torque settings and functional test procedures are verified by our engineering team.

Scalable Assembly Capacity

Suitable for prototype builds, pilot runs and stable mass production.

Shenzhen Supply Chain Advantage

Fast access to displays, plastic housings, metal parts, cables, batteries, sensors and modules.

Complete Functional Testing Capability

Every finished device undergoes validated FCT, power-on testing, sensor calibration or wireless connectivity testing if required.

Packaging & Labeling Ready for Shipment

Custom packaging, barcode labeling, serial number assignment and logistics support.

Box Build Assembly Capabilities

Mechanical Assembly

- Plastic and metal enclosure assembly

- Bracket and shield installation

- Display and touchscreen installation

- Sensor, switch and module mounting

- Mechanical alignment and fit checks

Cable & Harness Assembly

- Wire cutting and crimping

- Connector insertion and locking

- Cable routing and bundling

- Signal/power cable organization

System Integration

- PCBA installation

- Module interconnection

- Battery installation

- IO/terminal connection

- EMI shielding application

Firmware / Software Setup

- Bootloader flashing

- MCU/MPU firmware programming

- Wi-Fi/Bluetooth calibration

- Serial number / MAC address injection

- Config file loading

Quality & Process Control for Box Build

LinkPCBA ensures repeatable, engineering-verified final assembly quality.

Process Control

- Work instruction (WI) control

- Torque settings for screws

- Cable routing specification

- Assembly step sequence

- Mechanical fit verification

Functional Test (FCT)

- Power-on test

- Button & IO test

- Display & indicator validation

- Wireless / sensor test

- Motor / relay / actuator test

- RF/SNR measurement (optional)

Final Quality Control

- Aging/burn-in test (optional)

- Environmental test (optional)

- Final QC/visual inspection

- Packaging verification

Industries We Serve

IoT & smart home devices

Automotive aftermarket electronics

Industrial controllers

Medical & testing devices

Smart sensors

Consumer electronics

Wearables

Energy & power modules

Security & Communication Systems

Stable and interference-resistant PCBA for surveillance, access control, and communication infrastructure. Designed for 24/7 operation with EMC protection, shielding, and long-term component reliability.

Automotive Electronics

Precision PCBA manufacturing for automotive control units, ADAS systems, and EV battery management. All assemblies meet IPC Class 3 and IATF16949 standards for vibration resistance and long-term reliability.

Industrial Control Systems

Durable PCBA solutions for automation, robotics, and power management. High-temperature and high-current designs are validated through AOI, X-Ray, and functional testing to guarantee stability in demanding environments.

Medical Devices

Certified ISO13485 manufacturing for diagnostic, monitoring, and portable medical electronics. Every production stage follows traceable quality control to ensure safety, accuracy, and compliance with global medical regulations.

IoT & Smart Devices

Compact, energy-efficient assemblies for IoT modules, wearables, and smart-home systems. RF optimization and multi-protocol compatibility (Wi-Fi, BLE, LoRa) deliver reliable connectivity in small-form designs.

New Energy Systems

Reliable PCBA manufacturing for renewable energy applications, including solar inverters, energy storage systems, and EV charging infrastructure. Boards are designed for high current, heat resistance, and long operational lifespan under continuous load.

Success Stories from Global OEM & ODM Clients

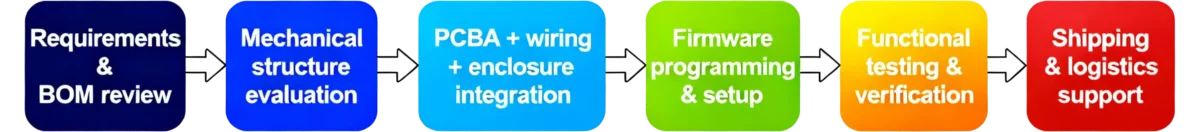

How We Work(Assembly Process Flow)

FAQ — Box Build Assembly

IoT devices, industrial controllers, smart sensors, automotive electronics, consumer devices and more.

Yes. We provide complete PCB → PCBA → box-build integration.

Yes. MCU, WiFi/Bluetooth modules, calibration data and serial number injection.

Yes. Mechanical and FCT fixtures can be developed for pilot and mass production.

Flexible. From prototype builds to mass production.

Start Your Box Build Assembly Project Today

Full-System Integration • Firmware Setup • Final Testing & Packaging

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team