Industrial Control & Automation PCB / PCBA Manufacturing

Industrial control electronics require long-term stability, precise signal integrity, and high reliability under continuous high-load operation. LinkPCBA provides engineering-driven PCB and PCBA manufacturing solutions for industrial automation, control systems, power modules, sensor units, PLC controllers, and industrial IoT devices.

With three Shenzhen production centers and a full one-stop service covering PCB fabrication, SMT, DIP, testing, assembly, and box build, we support global OEM & ODM customers with stable quality, fast response, and scalable mass-production capability for industrial control applications.

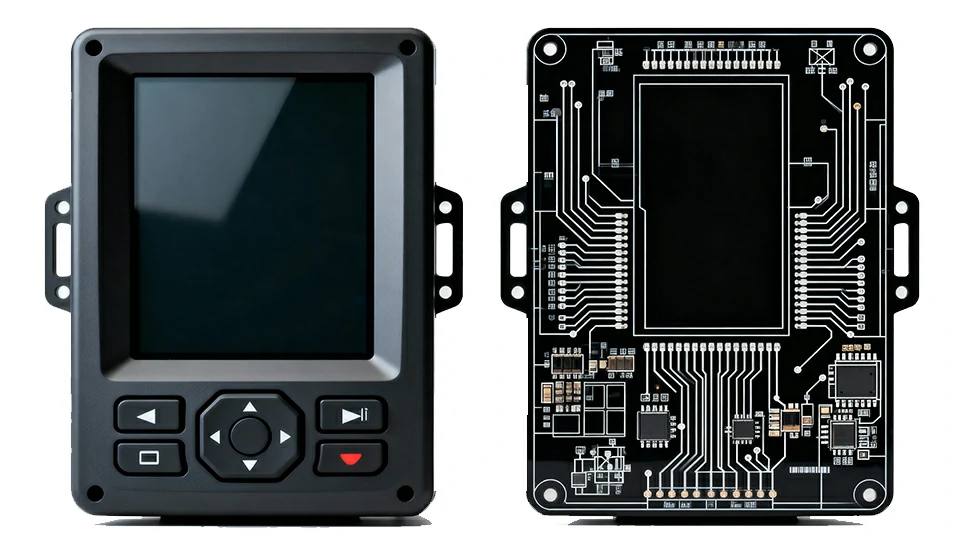

Customer Project Scenario — High-Reliability Industrial Control Systems

A global industrial automation company partnered with LinkPCBA to produce a multi-layer control board used in a servo driver module.

The project required:

- Reliable 24/7 operation under continuous load

- High-current copper structures for power conversion

- Stable high-speed signal integrity for control loops

- Anti-interference PCB design with strict EMC/EMI requirements

- Long lifecycle guarantee for industrial-grade components

- Small prototype batches followed by fast mass-production transition

LinkPCBA provided a fully validated PCB & PCBA manufacturing solution enabling rapid verification and stable volume production.

Technical Challenges in Industrial Control Electronics

Industrial automation electronics face extreme operating environments. Key technical challenges include:

- Continuous high-load operation

Industrial machines operate 24/7, requiring long-term thermal stability and durable solder joints. - High-current & power conversion

Motor drivers, power modules, and industrial power supplies often require heavy copper, thermal vias, and efficient heat dissipation. - EMC / EMI robustness

Industrial environments introduce strong electromagnetic noise; PCB layout, grounding, isolation spacing, and filtering must be precise. - Mixed-signal complexity

Analog, digital, and power circuits coexist on one board, requiring careful separation, impedance control, and signal loop optimization. - Long product lifecycle

Industrial customers require stable supply chain support for 5–10 years.

LinkPCBA Manufacturing Solution for Industrial Control Electronics

Engineering Support

- DFM & DFA for industrial-grade PCB stack-up

- High-current routing optimization and copper balancing

- Thermal management design: thermal vias, heat spreading, special substrates

- EMC/EMI layout optimization: grounding strategy, isolation spacing, shielding

- Assistance with component derating & long lifecycle planning

PCB Manufacturing

- 2–20 layer industrial control PCBs

- Heavy copper up to 6 oz for high-power modules

- High-temperature, high-Tg laminates for 24/7 operation

- Controlled impedance for control interfaces, CAN, RS485, industrial Ethernet

- LDI fine-line imaging for precise signal routing

- Surface finishes: ENIG, OSP, Immersion Tin, Hard Gold

PCBA Assembly

- High-precision SMT with SPI, AOI, and X-ray inspection

- Reliable soldering for power devices, transformers, relays

- DIP / wave solder or selective solder for connectors

- Potting, conformal coating, silicone protection for harsh environments

- Full traceability: lot tracking, labeling, and MES recording

Functional Tests & Reliability Validation

- ICT & FCT

- High-power load tests

- Thermal cycling & thermal shock tests

- Burn-in validation for long-term reliability

- Vibration testing for industrial motion systems

Industrial-Grade Production Capability

With three Shenzhen manufacturing centers, LinkPCBA offers:

- Prototype → NPI → Mass production

- 24-hour quick-turn sample options

- Industrial-grade component sourcing with stable availability

- Fast ECN response for design updates

- Dedicated engineering team for industrial automation projects

We ensure consistent quality and stable long-term delivery for global industrial customers.

Quality Assurance & Validation System

Industrial electronics require exceptional reliability. Our QA system includes:

- 100% AOI & SPI

- Multiple X-ray checkpoints

- High-voltage insulation & isolation tests

- Thermal cycling & aging tests

- Conformal coating & moisture protection

- Documentation package: inspection reports, test results, traceability data

Every batch undergoes rigorous validation to ensure fault-free operation in industrial environments.

Industrial Control Application Segments We Support

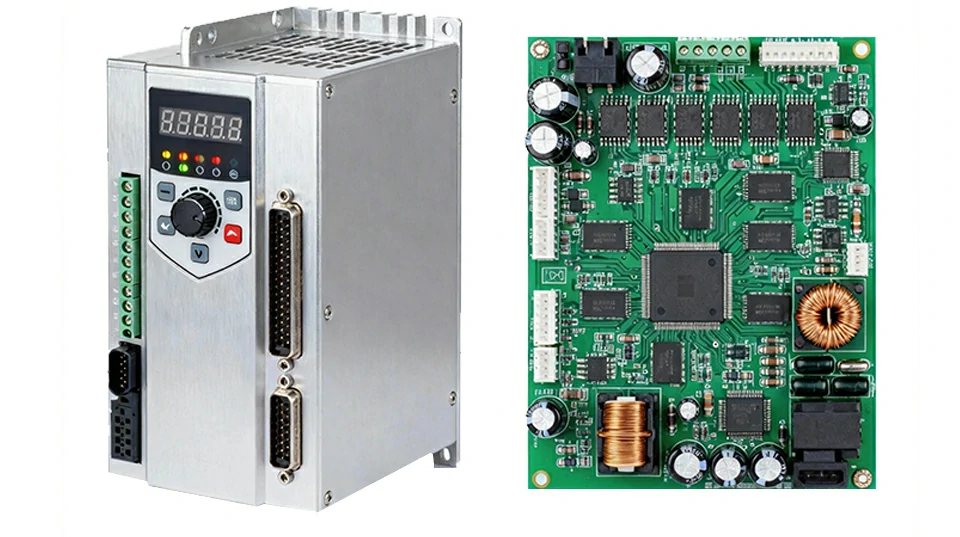

Motor Control & Servo Systems

Servo drivers, motor controllers, inverter boards, encoder systems

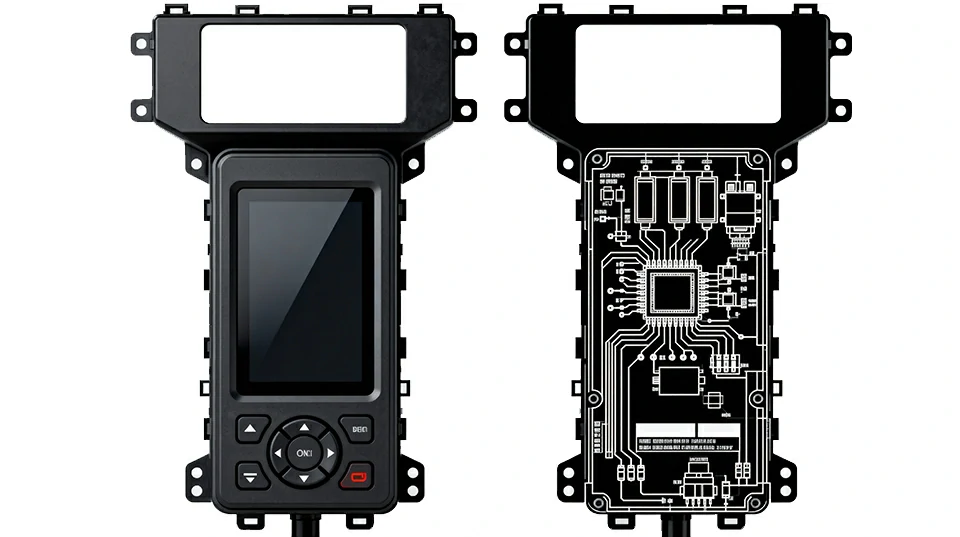

PLC & Automation Controllers

PLC modules, logic control boards, IO control units

Power Electronics

Industrial power supplies, converters, inverters, UPS modules

Industrial Networking

Industrial Ethernet, CAN, RS485, gateway modules

Sensors & Monitoring Systems

Temperature, pressure, flow, vibration sensors, data acquisition units

Automation Machinery & Robotics

Robot control boards, motion control, stepper driver modules

Why OEM & ODM Clients Choose LinkPCBA for Industrial Control Manufacturing

- Long-term reliability for 24/7 operation

Industrial-grade materials, stable process control, and robust soldering. - Full manufacturing chain in-house

PCB + SMT + DIP + testing + coating + assembly. - Fast engineering response

24-hour DFM, rapid prototyping, quick ECN handling. - High-power & mixed-signal expertise

Heavy copper, thermal optimization, and EMC/EMI design experience. - Stable supply chain & lifecycle support

Long-term sourcing for industrial-grade components.

Case Study — Industrial Servo Driver Control Board

LinkPCBA delivered:

- Heavy copper power section + controlled impedance signals

- Mixed analog/digital/power design optimization

- 0201–high-current components mixed assembly

- Conformal coating for dust and moisture protection

- Full functional testing and long-run validation

The project scaled from prototypes to mass production with stable performance.

FAQ — Industrial Control PCBA

Yes. We support heavy copper, thermal vias, and specialized materials for high-power electronics.

Yes. We use stable industrial suppliers with 5–10 year availability.

Yes. Our engineering team supports layout, grounding, and design optimization.

Yes. Conformal coating, potting, and silicone protection are available.

Yes. We specialize in mixed analog/digital/power industrial designs.

Start Your Industrial Control Project Today

LinkPCBA provides reliable, engineering-driven PCB & PCBA manufacturing for industrial automation and control systems.

Our engineering team responds within 24 hours for DFM, quotation, and technical support.

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team