Medical Devices PCB / PCBA Manufacturing

Medical electronic devices require exceptional reliability, precision, patient safety, and strict manufacturing controls. LinkPCBA provides end-to-end PCB and PCBA manufacturing solutions for diagnostic equipment, monitoring systems, portable medical devices, surgical tools, wearable health products, and imaging technologies.

With three Shenzhen manufacturing centers and a complete one-stop workflow—from PCB fabrication to SMT, DIP, testing, and final assembly—we support global medical OEM & ODM customers with stable quality, engineering support, and long-term mass-production capability.

Customer Project Scenario — High-Reliability Medical Electronics

A healthcare technology company partnered with LinkPCBA to produce a multilayer PCB assembly for a vital signs monitoring device.

The project required:

- Consistent performance under long-term continuous operation

- High accuracy and low noise for sensor signals

- Medical-grade material selection and production traceability

- Zero-defect soldering quality for patient-critical electronics

- Rapid prototyping followed by small-batch clinical trial runs

- Smooth transition into scalable mass production

LinkPCBA delivered a medical-grade manufacturing solution enabling precise engineering validation and reliable volume production.

Technical Challenges in Medical Electronics

Medical devices demand strict engineering controls and high reliability. Key challenges include:

- Patient-critical reliability requirements

Medical electronics must operate fault-free in life-critical environments. - High-accuracy, low-noise signal performance

PCB design must minimize noise, interference, and signal drift. - Compact, high-density electronics

Portable devices and wearables require HDI, fine-pitch components, and compact layouts. - Long-term stability & sterilization endurance

Materials must withstand cleaning, sterilization, and long-term storage. - Traceability & documentation compliance

Medical OEMs require complete traceability, batch records, and process validation.

LinkPCBA Manufacturing Solution for Medical Devices

Engineering Support

- DFM & DFA for HDI, fine-pitch components, and compact medical designs

- Sensor signal optimization: grounding, shielding, impedance control

- Material selection for long-term stability

- Biocompatible, low-ion contamination materials

- Risk mitigation & reliability engineering guidance

PCB Manufacturing

- Multilayer & HDI PCB for medical precision circuits

- Controlled impedance, low-noise routing

- High-Tg, medical-grade laminates

- LDI imaging for fine-line accuracy

- ENIG / ENEPIG for sensitive sensor interfaces

- Low-ion contamination, clean manufacturing processes

PCBA Assembly

- High-precision SMT with SPI, AOI, X-ray

- Medical-grade soldering quality

- Clean assembly environments for sensitive electronics

- Conformal coating for moisture and contamination protection

- Mixed assembly (0201, BGA, QFN, sensors)

- Full traceability with batch records and labeling

Functional Tests & Reliability Validation

- ICT & FCT

- Noise, sensitivity, and stability testing

- High/low-temperature and humidity tests

- Vibration and drop tests for portable devices

- Burn-in validation for long-term operation

Medical-Grade Production Capability

With three Shenzhen manufacturing centers, LinkPCBA supports:

- Prototype → clinical trial → mass production

- Rapid 24-hour prototype service

- Stable medical-grade component sourcing

- Fast ECN response

- Dedicated engineering support for medical OEM projects

We provide consistent quality and long-term supply stability.

Quality Assurance & Compliance

Medical devices require precise quality control. Our QA & compliance system includes:

- 100% AOI & SPI

- Multi-step X-ray inspection

- Cleanroom-grade handling procedures

- Component verification & quality traceability

- Environmental stress & stability testing

- Complete documentation and reporting package

- Each batch meets the traceability, reliability, and performance expectations of medical customers.

Medical Device Application Segments We Support

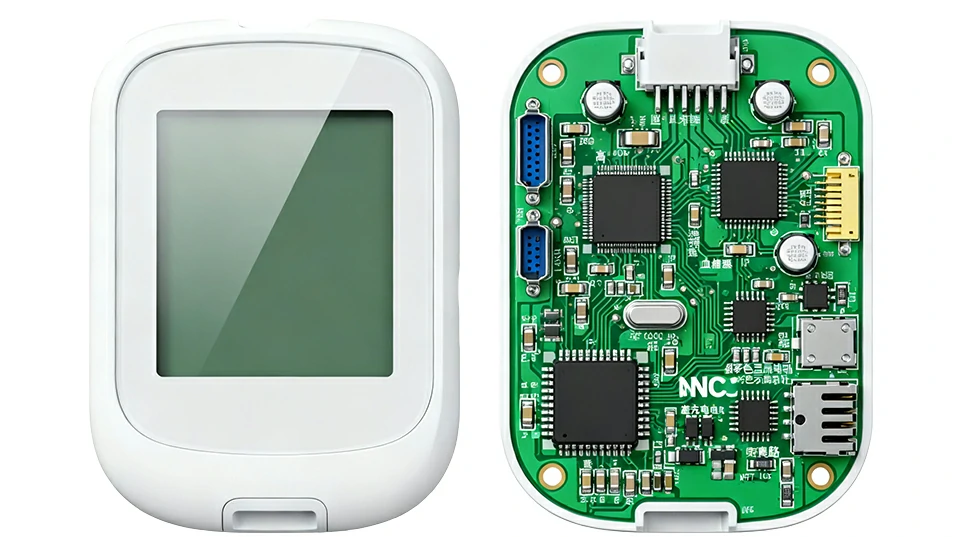

Patient Monitoring Systems

ECG, SPO2, blood pressure, temperature monitoring devices

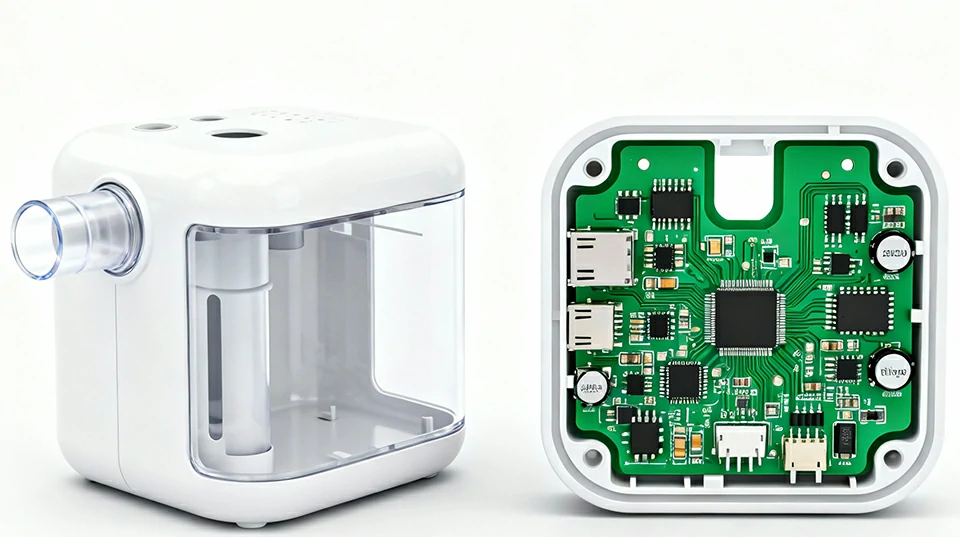

Diagnostic Equipment

Analyzers, imaging modules, lab diagnostic instruments

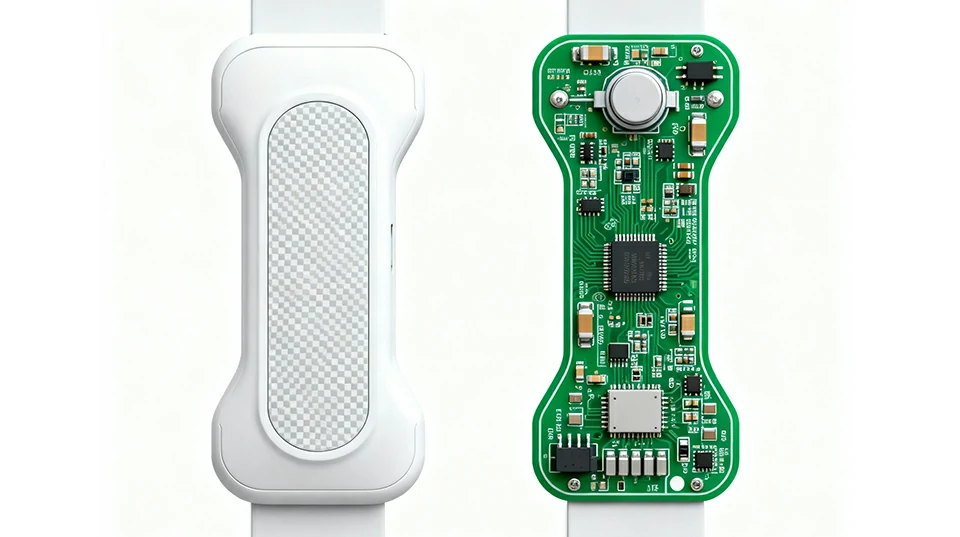

Portable / Wearable Devices

Health trackers, handheld scanners, point-of-care devices

Surgical & Therapeutic Electronics

Surgical tools, therapeutic stimulator boards

Sensor & Detection Modules

Biosensors, optical sensors, medical data collection units

Home Healthcare & IoT Medicine

Smart medical devices, remote monitoring electronics

Why OEM & ODM Clients Choose LinkPCBA for Medical Electronics

- Medical-grade reliability & precision

Strict quality control, clean environments, and stable long-term performance. - Complete one-stop manufacturing

PCB + SMT + DIP + testing + coating + assembly. - High-accuracy engineering support

Signal integrity, noise reduction, and sensor optimization. - Experience with clinical trial production

Fast iterations and small-batch builds for testing cycles. - Documentation & traceability

Batch tracking, quality records, and compliance reporting.

Case Study — Portable Vital Signs Monitoring Device

A customer required a 6-layer compact PCB assembly with sensitive sensor interfaces.

LinkPCBA delivered:

- High-precision HDI PCB

- Noise-reduction routing & shielding

- Mixed 0201 + sensor component assembly

- Conformal coating for environmental protection

- Full functional testing and long-term stability validation

The device successfully passed clinical evaluations and entered mass production.

FAQ — Medical Devices PCB / PCBA

Yes. We provide clean handling, traceability, and strict QA for medical electronics.

Yes. We specialize in prototype and pre-mass production for testing phases.

Yes. Our engineering team supports impedance, grounding, shielding, and noise reduction.

Yes. We offer conformal coating and protective treatments.

Yes. We work with stable suppliers to support long lifecycle requirements.

Start Your Medical Electronics Project

LinkPCBA provides precise, reliable PCB & PCBA manufacturing for medical devices, from prototype to long-term mass production.

Our engineering team responds within 24 hours.

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team