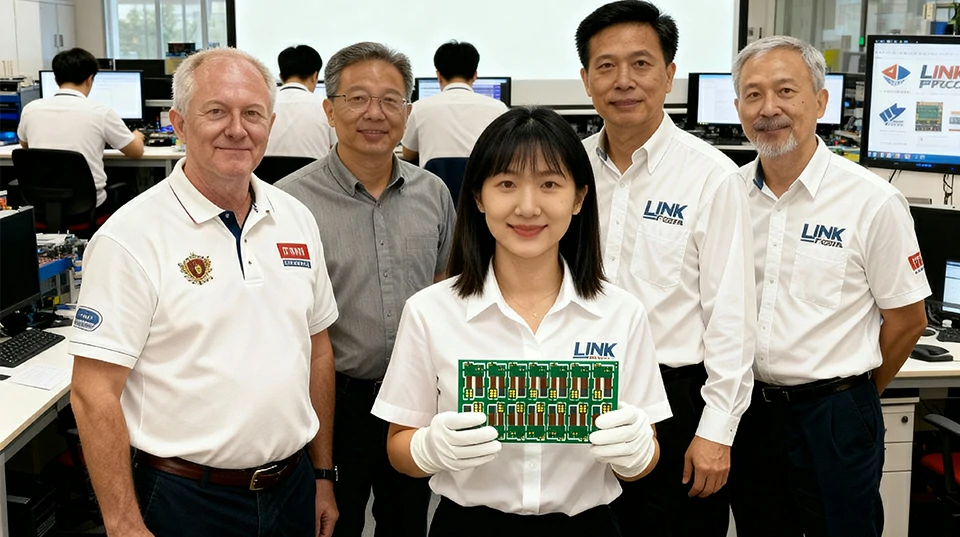

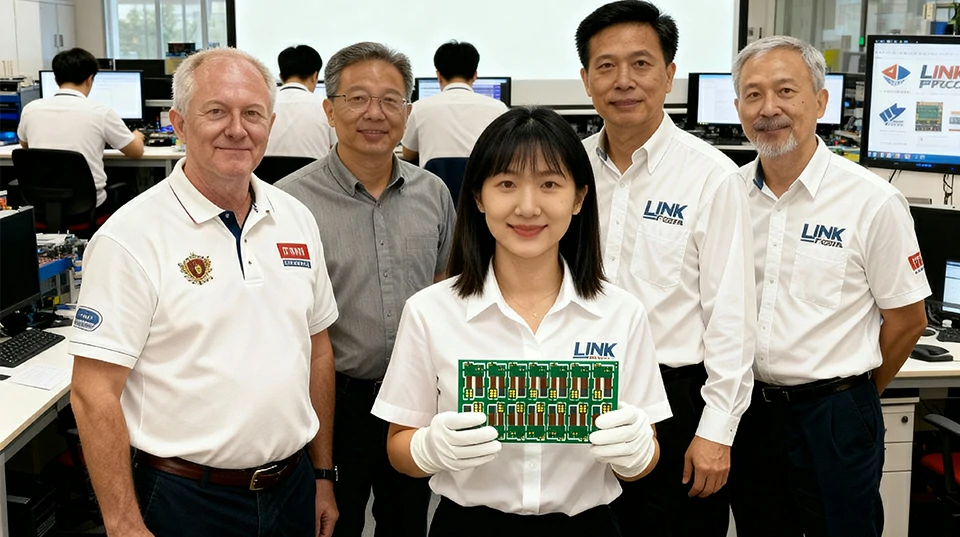

BOM & Component Sourcing Services — Reliable Supply Chain for PCBA Manufacturing

LinkPCBA provides professional BOM & Component Sourcing Services with full support for cost optimization, alternative part selection, supply chain verification, and 100% traceability.

Located in Shenzhen—the world’s largest electronics supply chain hub—we offer fast procurement cycles, authorized sourcing, and flexible material solutions for prototype, small batch and mass production PCBA projects.

Why OEM & ODM Clients Choose LinkPCBA for BOM & Component Sourcing

Authorized & Traceable Component Sourcing

- Direct procurement from authorized distributors, original manufacturers and vetted suppliers.

Fast Material Availability in Shenzhen

- Thousands of in-stock components available within hours, ideal for urgent prototype builds.

Cost Optimization & Alternative Recommendations

- Engineering-driven BOM review with replacement suggestions to reduce cost and shorten lead times.

Complete PCBA Supply Chain Integration

- BOM sourcing + PCB fabrication + SMT assembly + THT + testing all in one workflow.

Anti-Counterfeit Inspection & Full Traceability

- Every material batch is inspected, labeled and documented with traceable lot records.

BOM Sourcing Capabilities

Component Types We Source

- ICs / MCUs / processors

- Power devices / MOSFETs / regulators

- RF & wireless components

- Capacitors / resistors / inductors

- Sensors / MEMS

- Connectors / sockets

- Modules(WiFi / Bluetooth / GPS)

- Displays & touch panels

Procurement Channels

- Authorized distributors(Digi-Key, Mouser, Arrow)

- Original manufacturers

- Shenzhen in-stock suppliers

- Global spot-buy channels for urgent needs

- Long-term supplier partnerships

Engineering Support for BOM Optimization

Our engineering team helps ensure manufacturability before production starts.

- BOM cost analysis

- Part availability risk assessment

- Life-cycle (EOL/NRND) checking

- Alternative component recommendation

- Electrical parameter comparison

- Footprint & package compatibility review

- Supply chain risk mitigation

This enables customers to achieve both cost efficiency and long-term stability.

Material Inspection & Traceability System

IQC Material Inspection

- Packaging & label verification

- Manufacturer/MPN validation

- Electrical parameter testing

- Anti-counterfeit visual inspection

- Date-code & storage condition check

MSD Control

Moisture-sensitive components handled according to IPC/JEDEC standards.

Traceability Documents

- Lot tracking

- Material certificate files

- RoHS / REACH reports

Applications Supported

THT assemblies delivered by LinkPCBA are widely used in:

Industrial electronics

IoT devices

Power modules

Automotive electronics

Smart consumer devices

Medical electronics

Security & Communication Systems

Stable and interference-resistant PCBA for surveillance, access control, and communication infrastructure. Designed for 24/7 operation with EMC protection, shielding, and long-term component reliability.

Automotive Electronics

Precision PCBA manufacturing for automotive control units, ADAS systems, and EV battery management. All assemblies meet IPC Class 3 and IATF16949 standards for vibration resistance and long-term reliability.

Industrial Control Systems

Durable PCBA solutions for automation, robotics, and power management. High-temperature and high-current designs are validated through AOI, X-Ray, and functional testing to guarantee stability in demanding environments.

Medical Devices

Certified ISO13485 manufacturing for diagnostic, monitoring, and portable medical electronics. Every production stage follows traceable quality control to ensure safety, accuracy, and compliance with global medical regulations.

IoT & Smart Devices

Compact, energy-efficient assemblies for IoT modules, wearables, and smart-home systems. RF optimization and multi-protocol compatibility (Wi-Fi, BLE, LoRa) deliver reliable connectivity in small-form designs.

New Energy Systems

Reliable PCBA manufacturing for renewable energy applications, including solar inverters, energy storage systems, and EV charging infrastructure. Boards are designed for high current, heat resistance, and long operational lifespan under continuous load.

Case Studies

Case 1 — IoT Device Cost Reduction (32% Savings)

- Original WiFi module discontinued

- Provided 2 compatible drop-in replacements

- BOM cost reduced by 32%

- Lead time shortened by 12 days

Case 2 — Automotive Sensor Module Supply Chain Stabilization

- Replaced EOL MOSFET with long-life cycle model

- Material availability secured for 36 months

- Yield improved after matching thermal specs

FAQ — BOM & Component Sourcing

Yes. We prioritize authorized distributors and verified manufacturers.

Yes. Our engineering team provides alternative component recommendations.

Through IQC inspection, packaging validation and traceable lot control.

Yes. Shenzhen in-stock suppliers allow rapid sourcing for prototype builds.

Yes. We analyze life-cycle data (EOL/NRND) and future availability risks.

Start Your BOM & Component Sourcing Project Today

Authorized Suppliers • Cost Optimization • 100% Traceability

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team