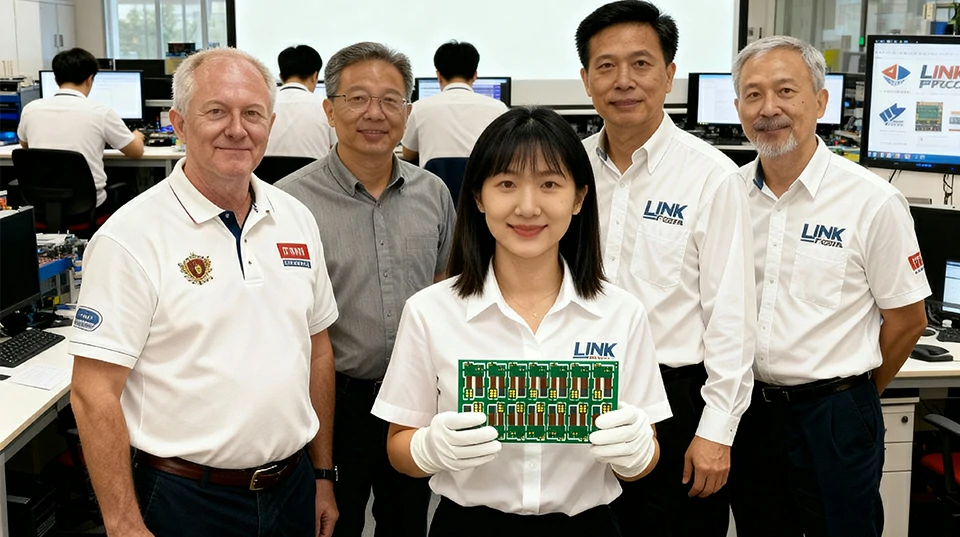

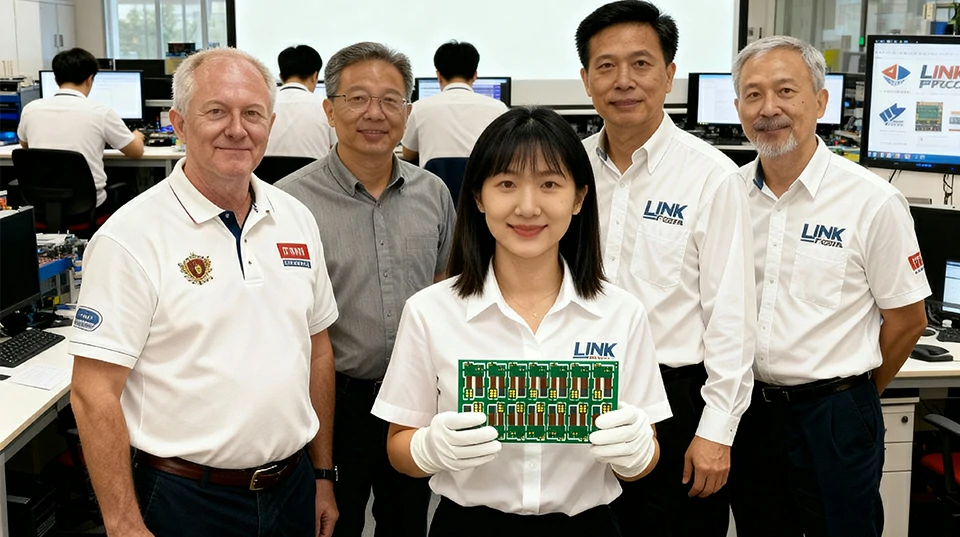

NPI & Rapid Prototyping — Fast PCBA Sample Builds & Engineering Validation

LinkPCBA provides NPI & Rapid Prototyping services tailored for fast iteration, engineering validation and smooth transition to mass production.

We support 24–72h rapid PCBA prototyping, small-batch trial runs and complete EVT/DVT/PVT engineering processes for OEM & ODM projects.

Why OEM & ODM Clients Choose LinkPCBA for NPI & Prototyping

Fast Prototype Lead Time(24–72 Hours)

- Ideal for early-stage design validation, proof-of-concept and urgent engineering builds.

Engineering-Driven NPI Process(DFM / DFT / DFR)

- Full support from PCB stack-up review to manufacturability, reliability and testability optimization.

From Prototype → Pilot Run → Mass Production

- Stable process rules and QC system ensure seamless transition across stages.

Small-Batch Flexibility(5–500 Units)

- Perfect for startups, hardware teams, and early engineering builds.

Controlled PCBA Manufacturing with Full Traceability

- Engineering supervision ensures consistent quality for every iteration.

NPI & Prototype PCBA Capabilities

Supported Prototyping Services

- PCB fabrication for prototype builds

- Rapid SMT assembly (01005 / fine pitch)

- THT / selective soldering

- Functional testing (FCT)

- Firmware programming

- Mechanical fit checks

- Material availability verification

Fast Prototyping Options

- 24 hours: Simple single/double-layer builds

- 48 hours: Complex SMT

- 72 hours: Mixed SMT + THT boards

Firmware Programming & Device Configuration

Supported Programming

- MCU programming

- WiFi/Bluetooth module burning

- RFID/NFC configuration

- Bootloader flashing

- Parameter calibration

- Serial number, MAC, AES key injection

Supported Interfaces

- SWD / JTAG

- UART / USB

- ISP / ICSP

- SPI / I²C

Engineering Support for NPI

- DFM review(layout, via structure, pad design)

- DFT test point planning

- DFR reliability analysis

- Thermal profile optimization

- Material selection & alternative component advice

- BOM risk review(EOL, NRND, supply risk)

- Panelization & tooling review

Engineering involvement ensures every prototype moves toward reliable mass production, not just “assembled quickly”.

EVT / DVT / PVT Development Stages

Ensures your design is ready for mass production.

EVT — Engineering Validation Test

- Electrical performance check

- Fit/function test

- Solder reliability verification

- Engineering bug fixing

DVT — Design Verification Test

- Build at higher sample quantity

- Refinement of process parameters

- Reliability and stress testing

- Firmware calibration

PVT — Pilot Verification Test

- Small-batch production simulation

- Testing fixture validation

- Supply chain verification

- Packaging & workflow confirmation

Applications

Our NPI & rapid prototyping service is ideal for:

IoT & smart hardware

Industrial controllers

Automotive modules

Medical testing devices

Wearables & consumer devices

Power electronics

Security & Communication Systems

Stable and interference-resistant PCBA for surveillance, access control, and communication infrastructure. Designed for 24/7 operation with EMC protection, shielding, and long-term component reliability.

Automotive Electronics

Precision PCBA manufacturing for automotive control units, ADAS systems, and EV battery management. All assemblies meet IPC Class 3 and IATF16949 standards for vibration resistance and long-term reliability.

Industrial Control Systems

Durable PCBA solutions for automation, robotics, and power management. High-temperature and high-current designs are validated through AOI, X-Ray, and functional testing to guarantee stability in demanding environments.

Medical Devices

Certified ISO13485 manufacturing for diagnostic, monitoring, and portable medical electronics. Every production stage follows traceable quality control to ensure safety, accuracy, and compliance with global medical regulations.

IoT & Smart Devices

Compact, energy-efficient assemblies for IoT modules, wearables, and smart-home systems. RF optimization and multi-protocol compatibility (Wi-Fi, BLE, LoRa) deliver reliable connectivity in small-form designs.

New Energy Systems

Reliable PCBA manufacturing for renewable energy applications, including solar inverters, energy storage systems, and EV charging infrastructure. Boards are designed for high current, heat resistance, and long operational lifespan under continuous load.

Case Studies

Case 1 — Smart Sensor Prototype to Mass Production

- 48-hour PCBA prototype

- Iterated 3 rounds of EVT builds

- Completed RF calibration & FCT testing

- Mass production launched within 6 weeks

Case 2 — Industrial Control Board NPI

- BOM optimization reduced cost by 22%

- DFT redesign improved yield during pilot run

- Passed thermal cycling & load testing

FAQ — NPI & Rapid Prototyping

24–72 hours depending on complexity.

Yes. Engineering review is included with every prototype project.

5 pcs.

Yes. We support EVT → DVT → PVT → full production.

Yes. We design custom test jigs for DVT/PVT builds.

Start Your NPI & Rapid Prototyping Project Today

Fast Builds • Engineering Validation • Smooth Transition to Mass Production

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team