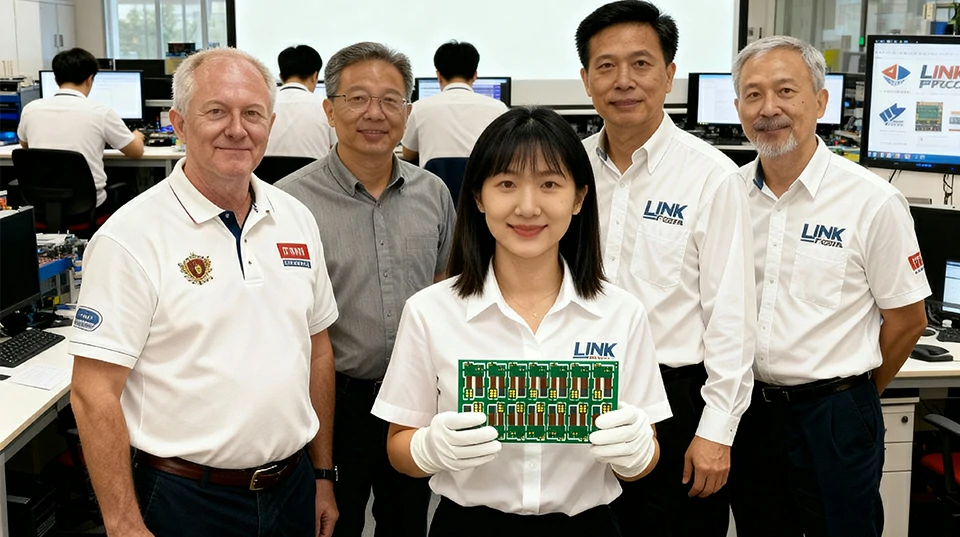

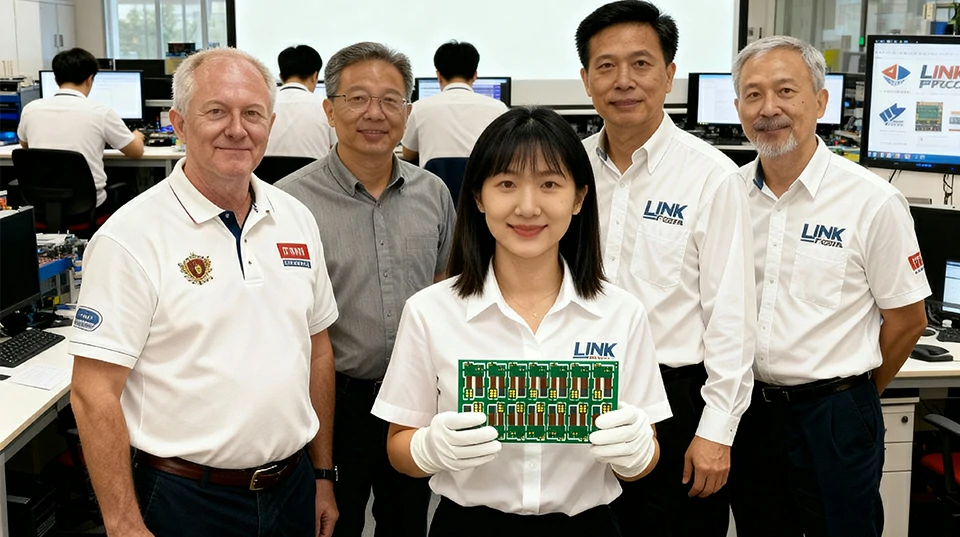

PCBA Testing & Programming Services — ICT, FCT & Firmware Programming

LinkPCBA provides professional PCBA Testing & Programming Services including ICT, FCT, functional testing, firmware burning, aging tests, and custom fixture development.

Testing is performed under strict engineering supervision to ensure reliability, stable performance, and production consistency for complex electronic products.

Why OEM & ODM Clients Choose LinkPCBA for PCBA Testing

Full Test Coverage from Prototype to Mass Production

- ICT, FCT, programming, boundary scan, power-up tests and EST (optional).

Engineering-Driven Test Development

- Custom test jig design, test procedures, and test scripts tailored to each project.

Reliable Functional Validation

- Ensures correct operation, I/O response, signal integrity and firmware behavior.

Firmware Programming & Calibration

- Support for MCU programming, RF calibration, serial-number injection and encryption.

Reduced Field Failures & RMA Risk

- Engineering-grade test coverage results in stable delivery and long-term reliability.

Testing Capabilities

ICT — In-Circuit Testing

- Opens/shorts detection

- Component value testing (R/C/L)

- Orientation & polarity verification

- Solder joint verification

- Test point optimization

FCT — Functional Test

- Power-on tests

- Signal integrity verification

- I/O and interface testing

- MCU/MPU behavior tests

- LED / sensor / RF / motor / relay function tests

Aging / Burn-In Test

- 2–24 hour aging

- Thermal stress testing

- Voltage cycling

- High-load tests for power electronics

Firmware Programming & Device Configuration

Supported Programming

- MCU programming

- WiFi/Bluetooth module burning

- RFID/NFC configuration

- Bootloader flashing

- Parameter calibration

- Serial number, MAC, AES key injection

Supported Interfaces

- SWD / JTAG

- UART / USB

- ISP / ICSP

- SPI / I²C

Custom Test Jig Development

- Mechanical jigs

- Bed-of-nails test fixtures

- Power-up test racks

- ICT & FCT combined fixtures

- RF/Sensor dedicated test stations

We design and build test fixtures according to customer requirements or Gerber + BOM + test specifications.

Quality System & Process Control for PCBA Testing

Testing is performed according to strict QA rules to ensure production-grade reliability.

Testing Workflow

Incoming PCBA → ICT → FCT → Aging (optional) → Debugging → Final functional test → Packing

Test Documentation Provided

- Test procedure

- Test report

- Debugging notes

- Pass/Fail data

- Traceability file

Standards

- IPC-A-610 Class 2 / 3

- ESG & reliability testing (optional)

- RoHS/REACH compliant production

Applications

PCBA testing and programming are widely used in:

IoT devices & gateways

Automotive electronics

Industrial controllers

Consumer electronics

Power modules & chargers

Wearable devices

Security & Communication Systems

Stable and interference-resistant PCBA for surveillance, access control, and communication infrastructure. Designed for 24/7 operation with EMC protection, shielding, and long-term component reliability.

Automotive Electronics

Precision PCBA manufacturing for automotive control units, ADAS systems, and EV battery management. All assemblies meet IPC Class 3 and IATF16949 standards for vibration resistance and long-term reliability.

Industrial Control Systems

Durable PCBA solutions for automation, robotics, and power management. High-temperature and high-current designs are validated through AOI, X-Ray, and functional testing to guarantee stability in demanding environments.

Medical Devices

Certified ISO13485 manufacturing for diagnostic, monitoring, and portable medical electronics. Every production stage follows traceable quality control to ensure safety, accuracy, and compliance with global medical regulations.

IoT & Smart Devices

Compact, energy-efficient assemblies for IoT modules, wearables, and smart-home systems. RF optimization and multi-protocol compatibility (Wi-Fi, BLE, LoRa) deliver reliable connectivity in small-form designs.

New Energy Systems

Reliable PCBA manufacturing for renewable energy applications, including solar inverters, energy storage systems, and EV charging infrastructure. Boards are designed for high current, heat resistance, and long operational lifespan under continuous load.

Case Studies

Case 1 — IoT Gateway Module Testing

- Combined ICT + functional testing

- Calibrated multiple sensors

- Programmed unique device IDs

- Achieved <0.1% test failure rate

Case 2 — Automotive Sensor Calibration

- Custom FCT jig

- Temperature compensation algorithm loaded

- Passed vibration and stress testing

FAQ — PCBA Testing & Programming

ICT, FCT, aging, power-up tests, and custom testing solutions.

Yes. We develop custom ICT/FCT jigs based on your product requirements.

Yes. We support SWD, UART, JTAG, ISP and other programming interfaces.

Yes. Full test documentation is provided for each batch.

Yes. We develop scalable testing systems for pilot and mass production.

Start Your PCBA Testing & Programming Project Today

ICT • FCT • Firmware Programming • Full Functional Validation

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team