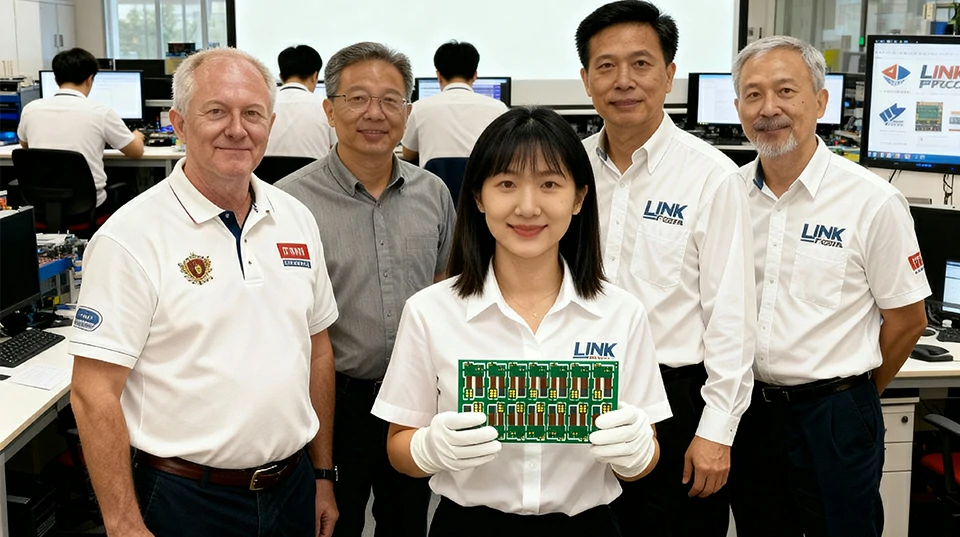

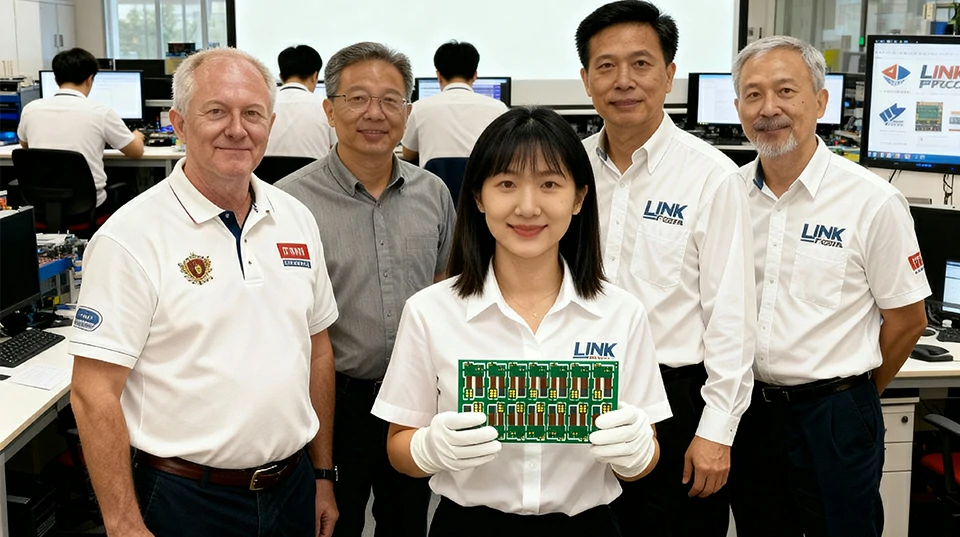

SMT Assembly Services — High-Precision, Fast Prototyping & Scalable Production

LinkPCBA provides high-precision SMT assembly services supporting fast prototyping, small-batch builds and stable mass production in Shenzhen, China.

Our SMT lines are equipped with Yamaha/ASM high-speed placement machines, 3D SPI, AOI and X-ray inspection, ensuring consistent soldering quality and reliable performance for advanced electronic products.

Why OEM & ODM Clients Choose LinkPCBA for SMT Assembly

Our SMT capability is optimized for complex, high-density and reliability-critical applications.

High-Precision SMT Lines(01005 / 0201 / Fine Pitch)

- Placement accuracy down to 01005 and 0.25 mm pitch, ideal for miniaturized and high-speed circuits.

Stable Production for Prototypes → Small Batch → Mass Production

- Identical process rules, reflow profile, and QC system across all stages.

Engineering-Driven Process(DFM / DFT)

- Full support for stencil design, pad optimization, thermal balance, and reflow simulation.

Full Inspection Chain(SPI → AOI → X-ray)

- Covers solder paste volume, component placement, BGA voids, QFN wetting, and hidden defects.

Shenzhen Supply Chain Advantage

- Access to authorized components, fast replenishment, and flexible material sourcing.

Rapid Prototyping(24–72h)

- Assembly for engineering samples, EVT/DVT builds and pilot runs.

SMT Assembly Capabilities

Component Types

- 01005 / 0201 micro components

- Fine-pitch ICs(0.25 mm)

- BGA / uBGA

- QFN / LGA / CSP

- Shielding cans & RF modules

- Connectors / sockets / odd-shape parts

Machine Capability

- Yamaha / ASM high-speed placement

- Up to 40,000–70,000 CPH

- Multi-zone reflow ovens

- Lead-free RoHS production

Advanced Processes

- Mixed technology(SMT + THT)

- Dual-sided SMT

- Large board support

- RF & high-speed soldering control

- Thermal mass balancing

- Underfill & conformal coating (on request)

Engineering Support — The Heart of Reliable SMT

Our engineering team ensures stable soldering quality before assembly begins.

- Stencil thickness & aperture design

- Pad optimization for QFN / BGA / CSP

- Thermal simulation & reflow curve adjustment

- Component orientation & polarity planning

- Solder mask & copper exposure review

- Panelization with break-off tabs & tooling holes

- Special handling for high-power & RF boards

Engineering involvement is what allows stable yield and predictable performance.

SMT Inspection & Quality Control

Inspection Flow

SPI → Reflow → AOI → X-ray → Visual confirmation → ICT/FCT(if required)

Inspection Capability

- 3D SPI solder paste measurement

- AOI for misalignment, tombstoning, shorts, missing parts

X-ray for:

- BGA voids

- QFN solder coverage

- LGA hidden joints

Quality Standards

- IPC-A-610 Class 2 / Class 3

- RoHS / REACH compliance

- Full traceability with batch tracking

Applications

SMT assemblies at LinkPCBA are widely used in:

Industrial Automation

Automotive Electronics

Medical & Healthcare Devices

Consumer Electronics

IoT & Smart Hardware

New Energy & Power Systems

Security & Communication Systems

Stable and interference-resistant PCBA for surveillance, access control, and communication infrastructure. Designed for 24/7 operation with EMC protection, shielding, and long-term component reliability.

Automotive Electronics

Precision PCBA manufacturing for automotive control units, ADAS systems, and EV battery management. All assemblies meet IPC Class 3 and IATF16949 standards for vibration resistance and long-term reliability.

Industrial Control Systems

Durable PCBA solutions for automation, robotics, and power management. High-temperature and high-current designs are validated through AOI, X-Ray, and functional testing to guarantee stability in demanding environments.

Medical Devices

Certified ISO13485 manufacturing for diagnostic, monitoring, and portable medical electronics. Every production stage follows traceable quality control to ensure safety, accuracy, and compliance with global medical regulations.

IoT & Smart Devices

Compact, energy-efficient assemblies for IoT modules, wearables, and smart-home systems. RF optimization and multi-protocol compatibility (Wi-Fi, BLE, LoRa) deliver reliable connectivity in small-form designs.

New Energy Systems

Reliable PCBA manufacturing for renewable energy applications, including solar inverters, energy storage systems, and EV charging infrastructure. Boards are designed for high current, heat resistance, and long operational lifespan under continuous load.

Case Studies

Case 1 — High-Density Wearable PCB(01005 + BGA)

- Solved QFN voids with optimized stencil design

- Refined reflow curve for temperature-sensitive BLE chip

- Delivered 12+ production batches with stable yield

Case 2 — Automotive Sensor Module

- Dual-sided SMT + selective solder

- Achieved <0.12% defect rate

- Completed environmental stress test (EST) and vibration test

FAQ — SMT Assembly

01005 and 0.25 mm pitch ICs.

Yes, with full inspection and process control.

Yes. 24–72h depending on complexity.

SPI, AOI, X-ray and IPC-A-610 Class 2/3 standards.

Gerber, BOM, Pick-and-Place (CSV/TXT), and assembly drawings.

Start Your SMT Assembly Project Today

Fast Prototyping • High-Precision Assembly • Full Inspection

⭐ Updated April 2025 — Reviewed by LinkPCBA Engineering Team